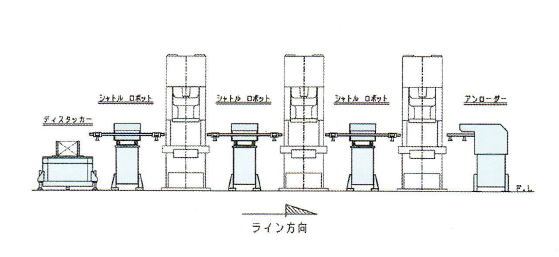

Dual Servo Transfer Robot Lines for LCD TV

and Micro Oven:

Servo driven transfer robot's pioneer, whose result is for more than 25

years, hereby defines

2 axis servo transfer robot for

double crank and straight side stamping presses.

Features:

- . You can configure the production line for LCD TV and Plazma TV back panels

at the reasonable price.

- As Shuttle Robot can transfer the components directly without idle stage,

the following merits come out.

a.As the number of pick up arm becomes approximately half,

a−1. You can save the cost for half of pick up arms and idle stages.

a−2. You can save the set-up time for half of pick up arms and idle stages.

a−3. Production stop probability becomes lower for half of pick up arms

and idle stages.

a−4. Large sized components are transferable by shorter line lay-out.

a−5. Installation space is 2/3 when compared with conventional transfer

lines.

- You can choose intermidiate and direct mode in case idle stages are installated.

- You can enjoy the merits a-2, a-3 and a-4 mentioned above.

- You can set pick up arm motion and speed freely by means of 2 axis servo

driven system.

|

|